Press Number

Updated June 15, 2024

The system allows a single component to calculate multiple presses. This allows the paper, presses and inks to be defined to specific press numbers.

The following are examples that illustrate the procedures.

-

Assigning Inks to a specific Press Number.

-

Assigning Materials to a specific Press Number.

Inks assigned to a specific Press Numbers

A Print Shop has a press specifically set up for coating sheets. This is separate from their main press which is, by way of example, a 4 color 40" Press. Jobs are printed on the main press and if needed run through the second press to perform the coating.

Define Inks:

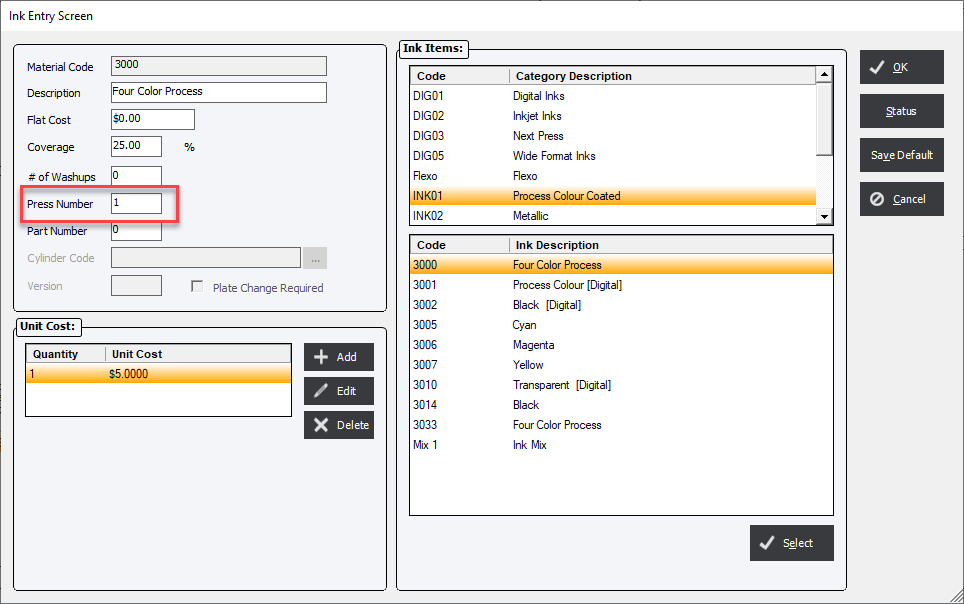

Enter in the main press inks and assign them to Press Number 1. By default this is set to 0.

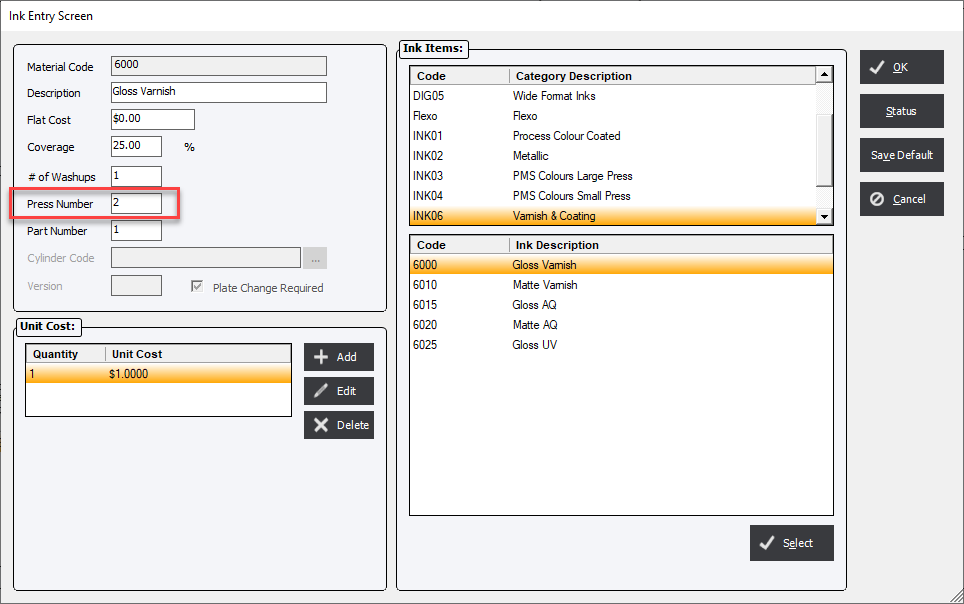

Enter and assign the coating inks to Press Number 2.

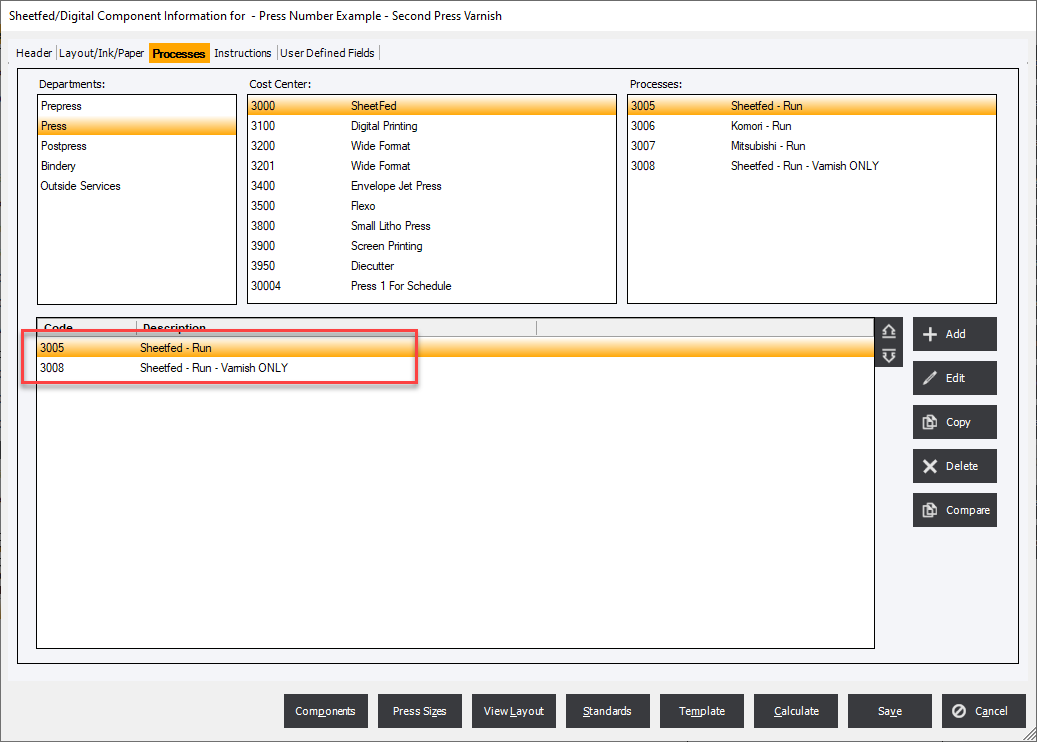

Next add both presses to use.

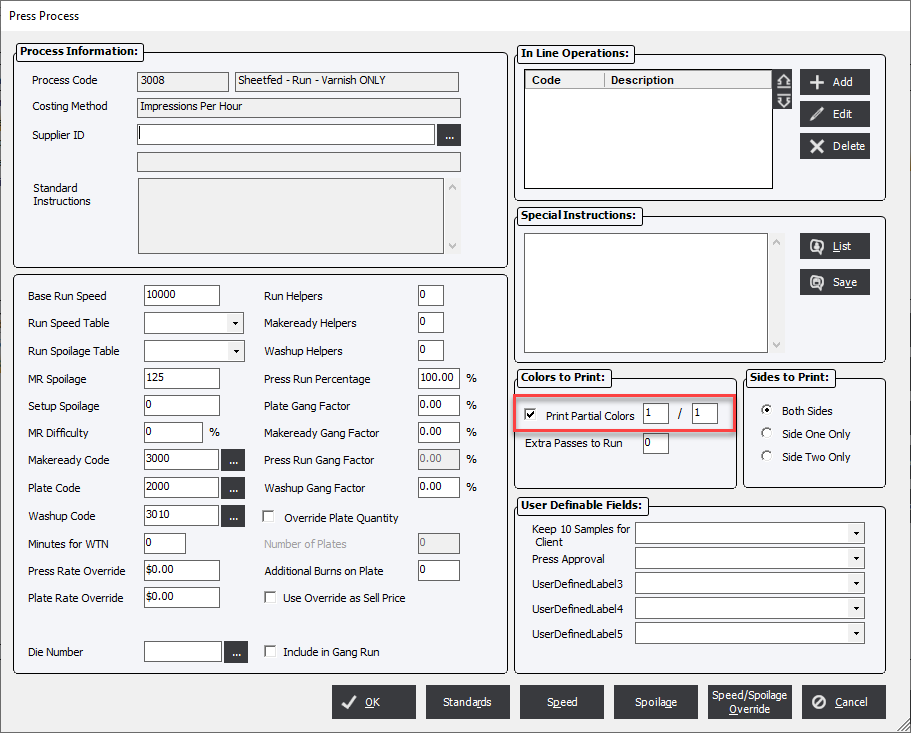

On the second press define the Print Partial Colors to the number of inks to print side 1 and side 2.

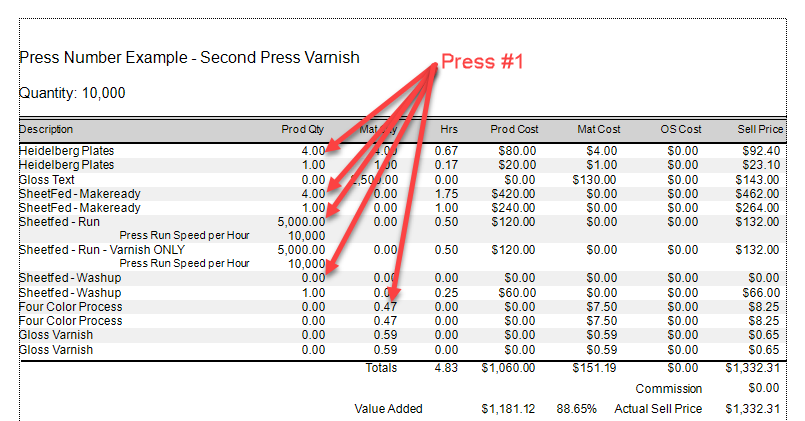

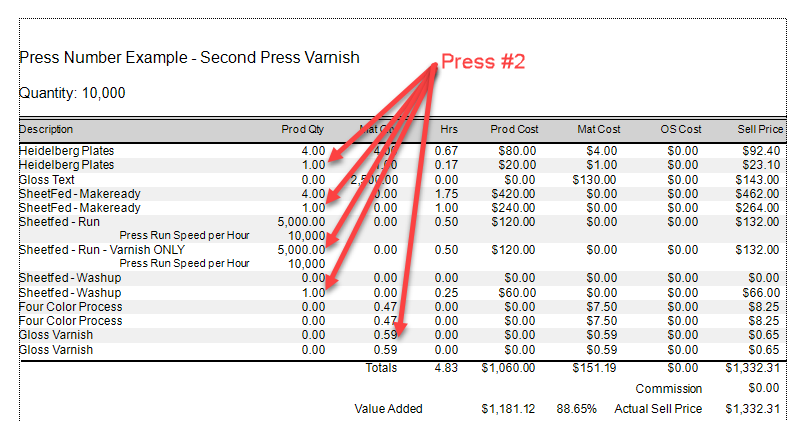

Calculate to confirm.

Press # 1

Press #2

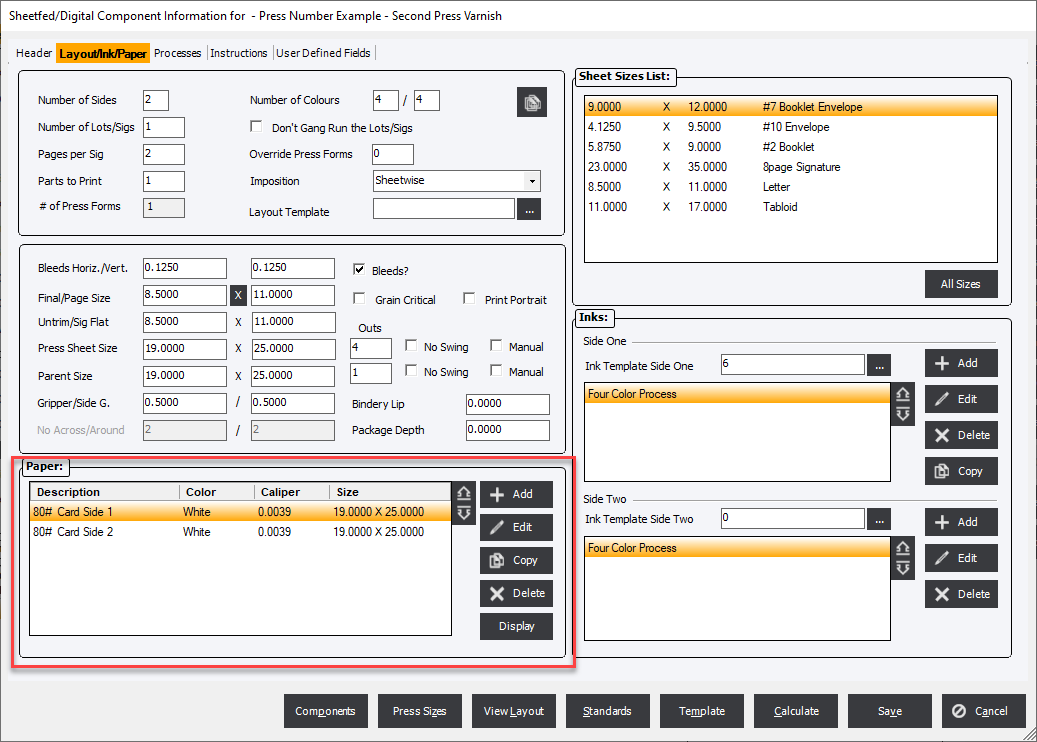

Material assigned to specific press

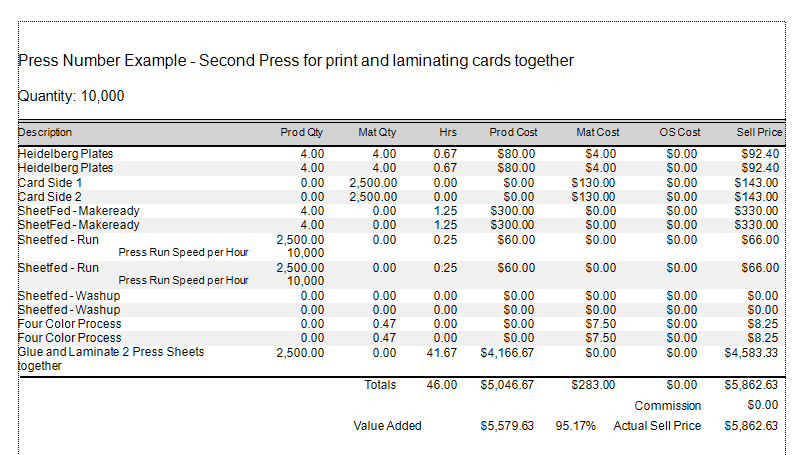

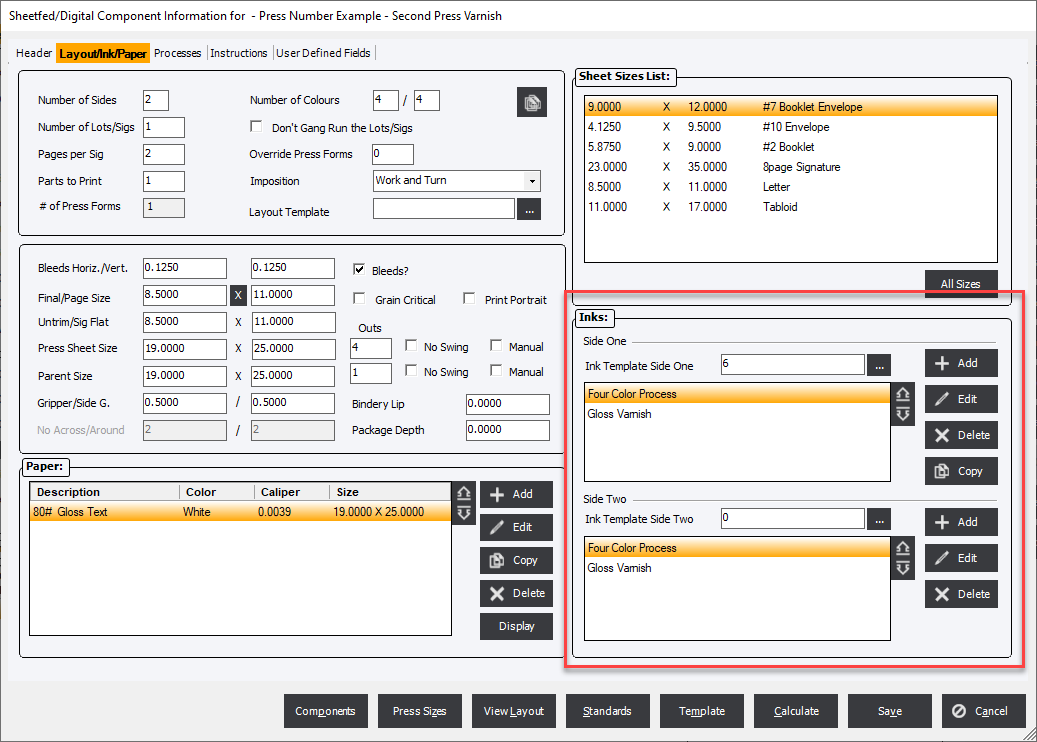

A gift card manufacture requires 2 substrates for a card : Front and Back each printed with different images. They will be laminated together in a bindery process.

Add and assign materials to specific presses.

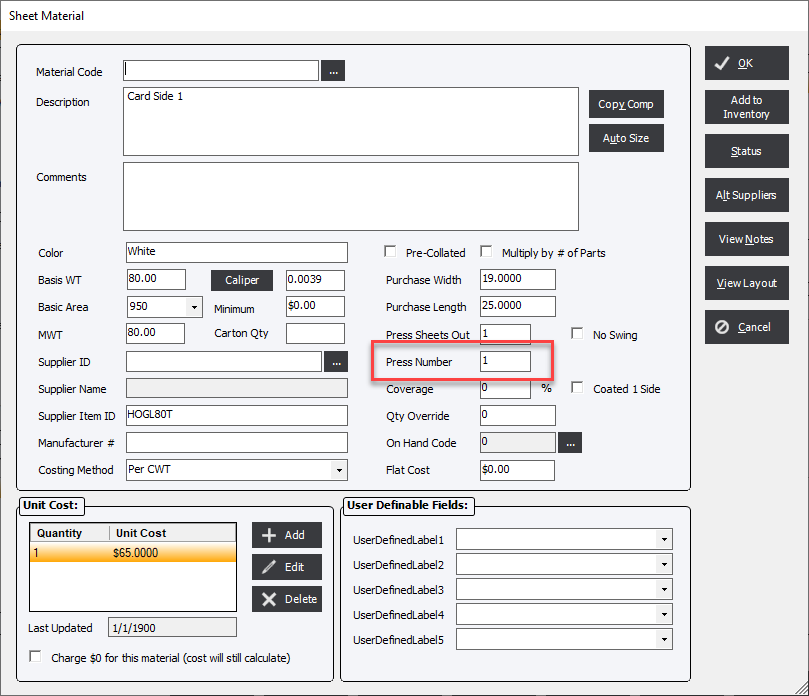

Material #1 : Changed the Press Number from the default of 0 to 1.

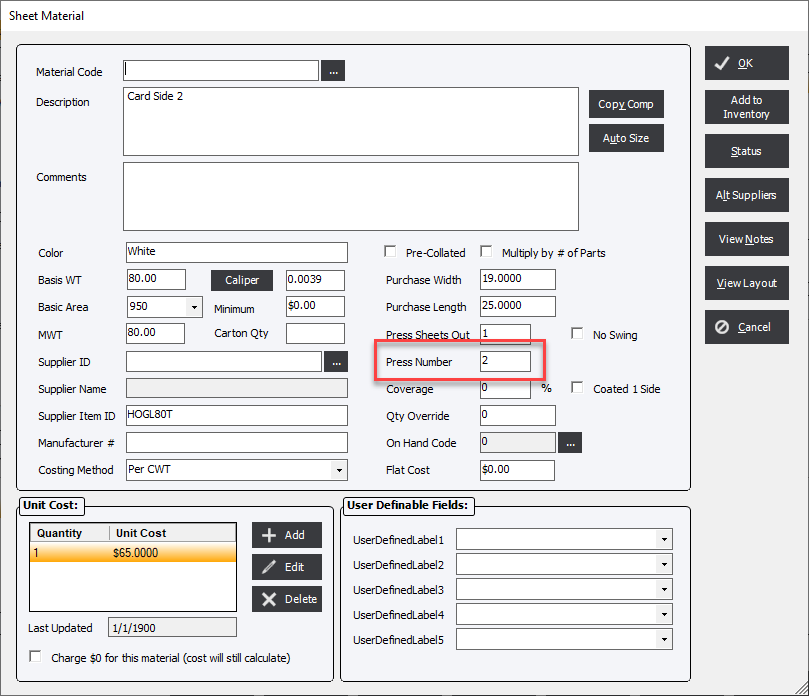

Material #2 : Changed the Press Number from the default of 0 to 2.

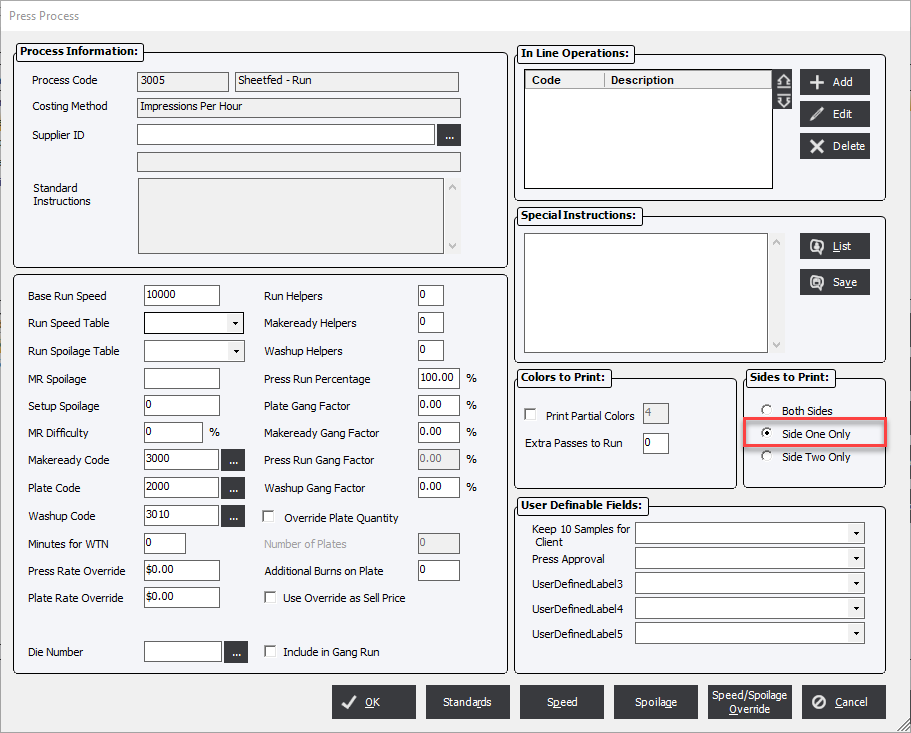

Add Press Number 1 and change the Sides to Print to Side One Only.

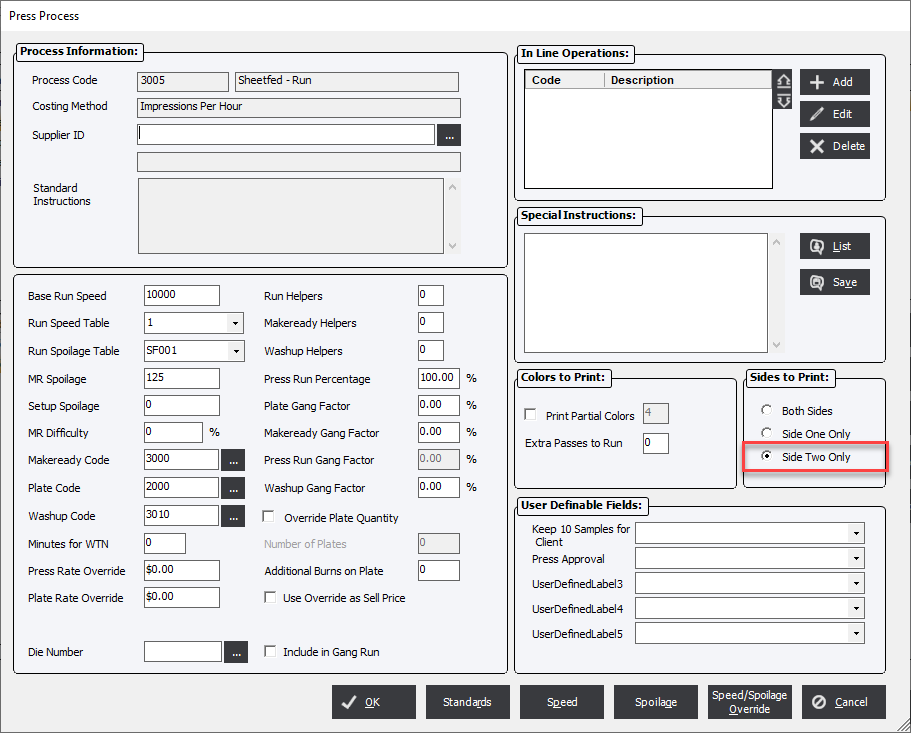

Add Press Number 2 and change the Sides to Print to Side Two Only.

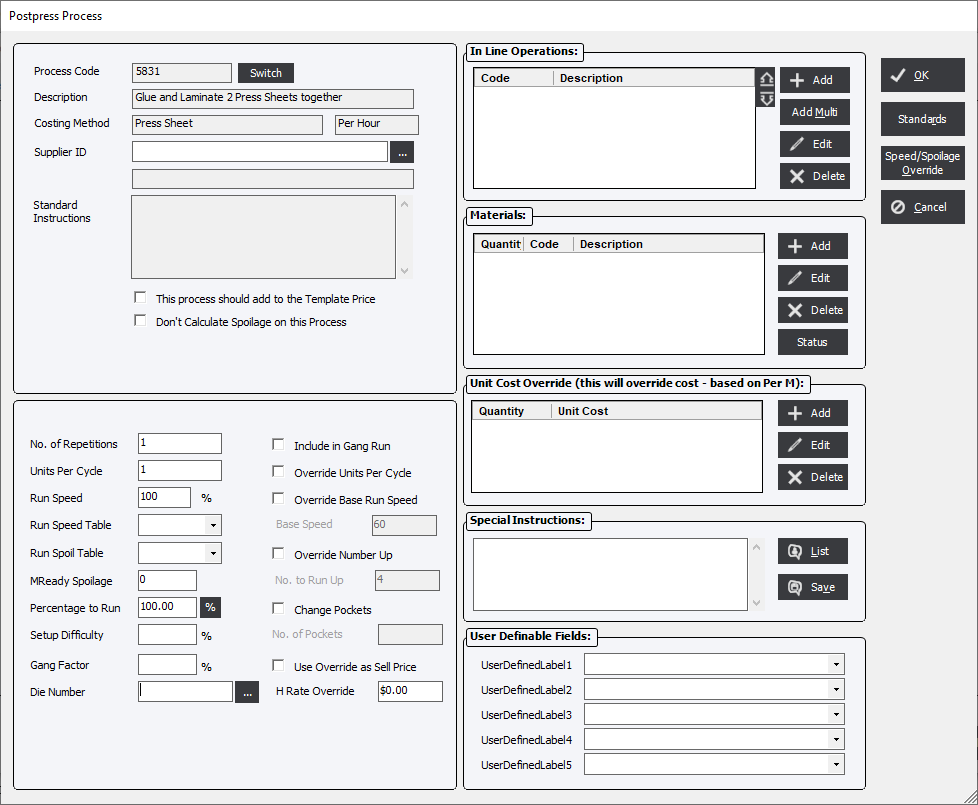

Add Laminating Postpress process.

Calculate to confirm.