Units per Hour

Updated October 21, 2022

Applies to : Press and HSC Process

Press

Enter a value that the press will achieve per hour in normal production that corresponds with the Costing Method chosen.

Costing Method : Impressions Per Hour

This is the way a traditional press calculates the quantity required.

Press Time = (Press Sheets * Number of Side * Passes ) / Units per Hour

Costing Method : Feet per Minutes

Typically used for Flexo presses.

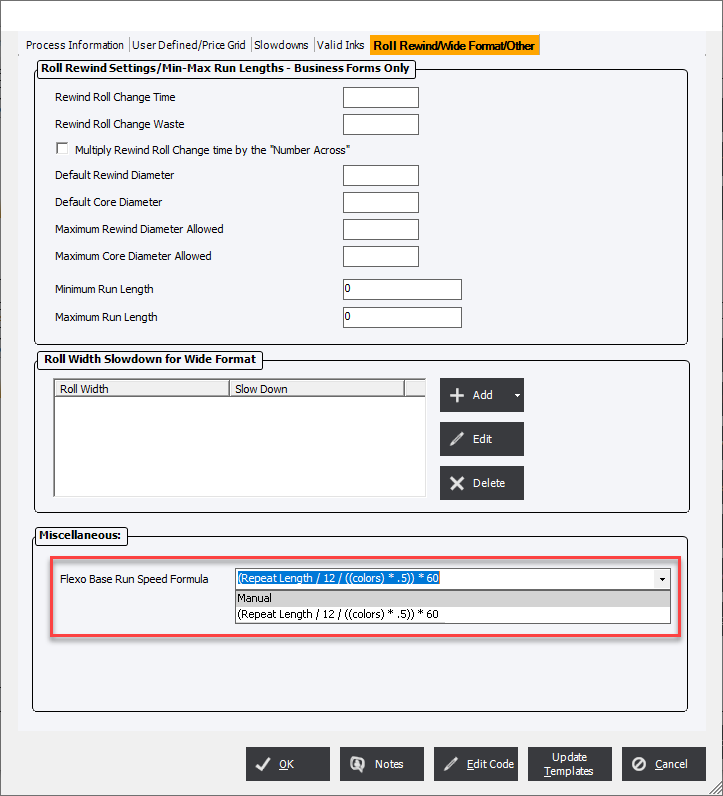

There are 2 ways the calculation will work depending on the option set in the Roll Rewind/Wide Format/Other tab

Manual

|

|

Formula : Press Quantity in Feet = (Quantity * (Size Around + Space Around )) / 12 * this should equal the cylinder around value. See Max Up ... feature to automatically calculate these values. |

|

|

(10,000 * ( 6 + 2 )) /12 = 6,667 |

|

|

|

|

|

Formula : Production Time = Press Quantity in Feet / (Feet per Minute *60) |

|

|

6,667 / (1000 * 60) = 6.67 hours |

Calculation specifically for the HP Indigo WS6800

|

|

Formula : ( Size Around + Space Around ) * Number Around = Repeat Length * this should equal the cylinder around value. See Max Up ... feature to automatically calculate these values. |

|

|

( 5 + 0.5 ) * 2 = 5.5 * 7 = 38.5 ( Repeat Length) |

|

|

|

|

|

Formula : (Repeat Length / 12 /((colors) * .5 )) * 60 |

|

|

( 38.5 / 12 / ( 4 *.5 )) * 60 = ( 3.21 / 2 ) * 60 = 1.604 * 60 = 96 feet per minute or 5760 feet per hour |

Costing Method : Feet per Minute

This costing method should be used for perfecting presses that with remain in perfecting mode. The calculation will efffectively reduce the press speed in half to accommodate the

| Costing Method | Corresponds to |

| Impressions Per Hour | Sheet through the press |

| Feet per Minute | |

| Sheets per Hour | |

| Square Feet | Square feet based on Press Sheet |

| Linear Feet | Linear feet based on Press Sheet |

| Stitches per Hour | Embroidery only |

Impressions Per Hour, Feet Per Minute or Sheets Per Hour, as applicable.