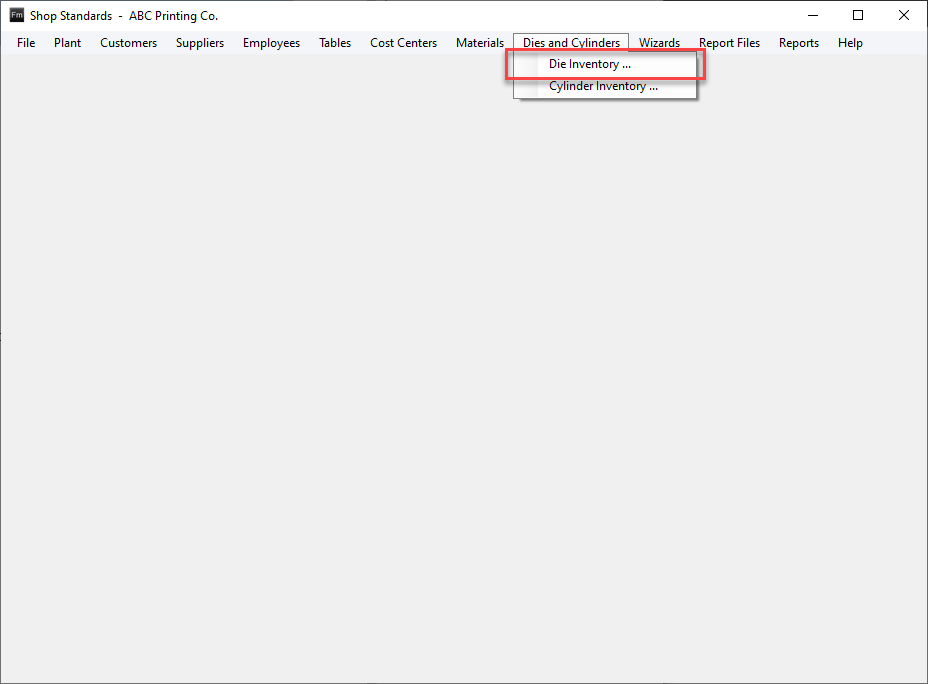

Die Inventory

Updated April 27, 2023

Eclipse allows the user to create a die inventory database for use in estimates and orders. This can also be a way of cataloging and storing information such as location, images and last time that the die was retooled.

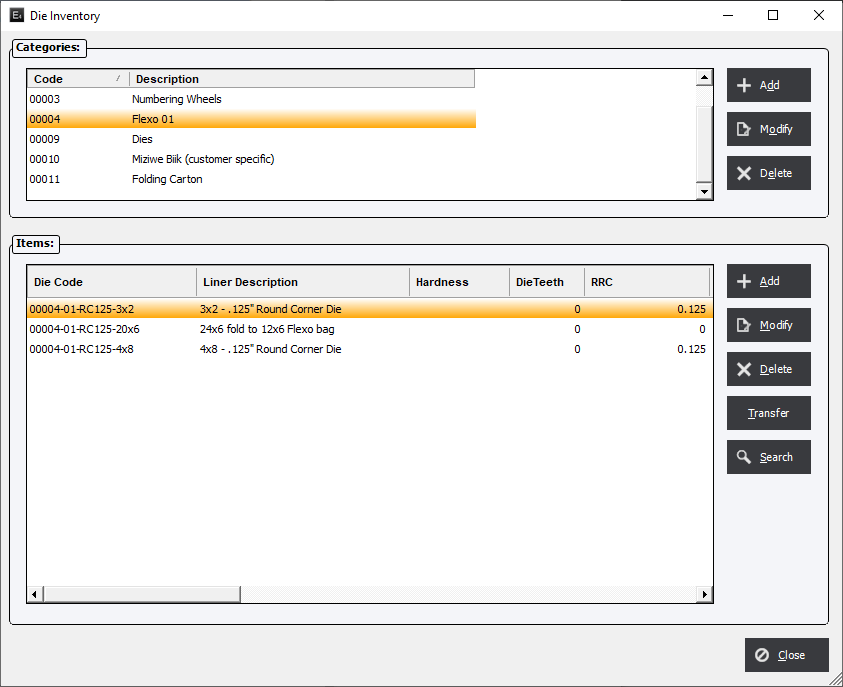

The module separates the inventory into Categories and Items so that all the dies can be easily located.

Each individual die (item) can have specifications for estimating purposes in the case of Flex printing or simply as information that will help identify the specific die and its intended uses.

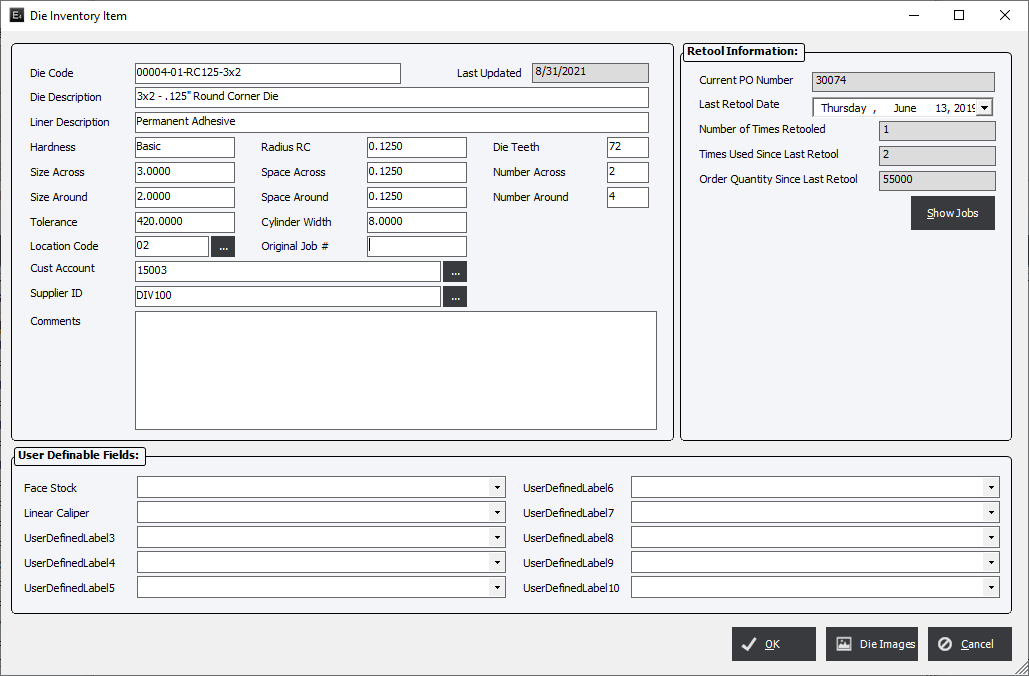

| Field |

Flexo Specific |

Informational Only |

Uses |

|

Die Code |

|

|

Alpha Numeric 50 digit number. |

|

Last Updated |

|

|

Date of the last time the item was saved from this screen. |

|

Die Description |

|

|

Basic Description of the die. This will print on the Purchase Order if a new die is ordered. |

|

Linear Description |

|

✓ |

Used to describe the backing of label stock. for example; Permanent Adhesive, Semi-Permanent Adhesive, Removable Adhesive, Piggyback. |

|

Hardness |

✓ |

✓ |

Used to describe any hardening of the die. |

|

Size Across |

✓ |

|

Size Across of the label oriented across the Flexo Cylinder. |

|

Size Around |

✓ |

|

Size Around of the label oriented around the Flexo Cylinder. |

|

Tolerance |

✓ |

|

Height of die. |

|

Location Code |

✓ |

|

Physical location of the die as set up in the locations settings. |

|

Customer Account |

✓ |

|

If this is selected only quotes/orders for that specific customer will be able to see and access this die. |

|

Supplier ID |

✓ |

|

Used if a Purchase Order to replace the die is required. The |

|

Comments |

|

✓ |

Generic Comments. |

|

Radius RC |

|

✓ |

The radius of the corners on the label. |

|

Space Across |

✓ |

|

Space between labels oriented across the cylinder. Similar to bleed. |

|

Space Around |

✓ |

|

Space between labels oriented around the cylinder. Similar to bleed. |

|

Cylinder Width |

✓ |

|

The width of the sheet to run. |

|

Original Job # |

|

|

The first job to use this die. |

|

Die Teeth |

✓ |

|

Number of teeth in the cylinder. This allows for different gear ratios to accurately calculate the number around the cylinder. |

|

Number Across |

|

|

Number of labels across the cylinder or flat die. For Flexo this number is used to help calculate the number up on a cylinder. |

|

Number Around |

|

|

Number of Labels around the cylinder or flat die. For Flexo this number is used to help calculate the number up on a cylinder. |

|

User Definable Fields |

|

✓ |

Standard UDF's that can be used however needed. |

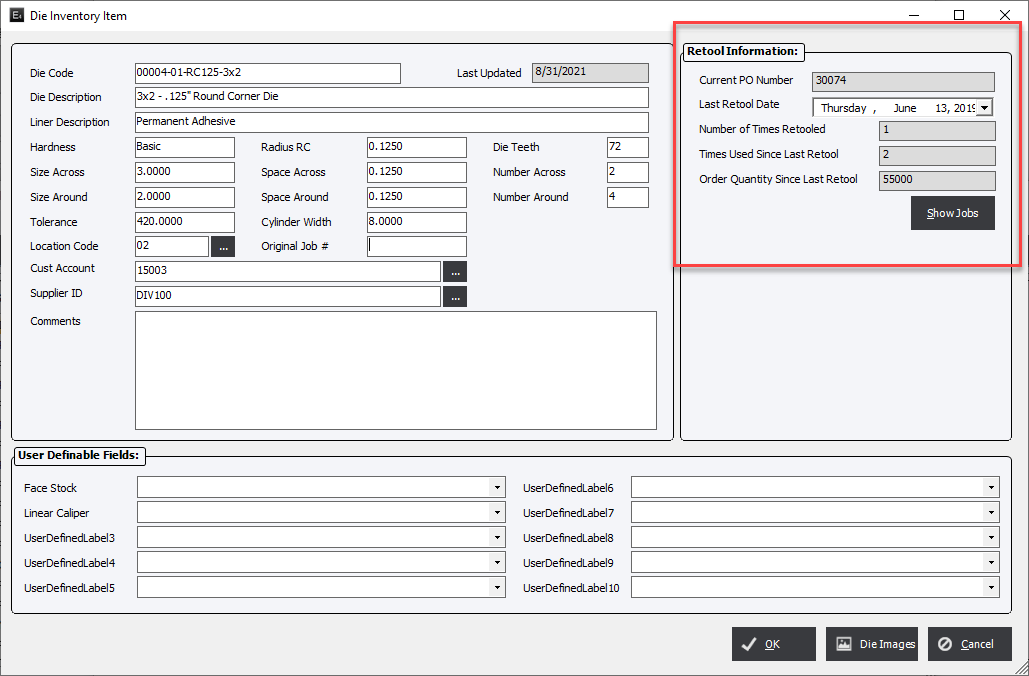

Retool Information

The Retool feature allows the system to keep track of the specific jobs that the die was used on and how many times it has been retooled.

Current PO Number : Shows the current open purchase order with the die and the last date it was retooled.

Last Retool Date : Once the PO is closed the Last Retool Date will be updated.

Number of Times Retooled : The total number of times the die has been retooled based on the number of closed PO's.

Times Used Since Last Retool : Number of jobs that the die was used on not including any open PO's.

Order Quantity Since Last Retool : Based on the quantity of finished pieces NOT the quantity divided by the number up.

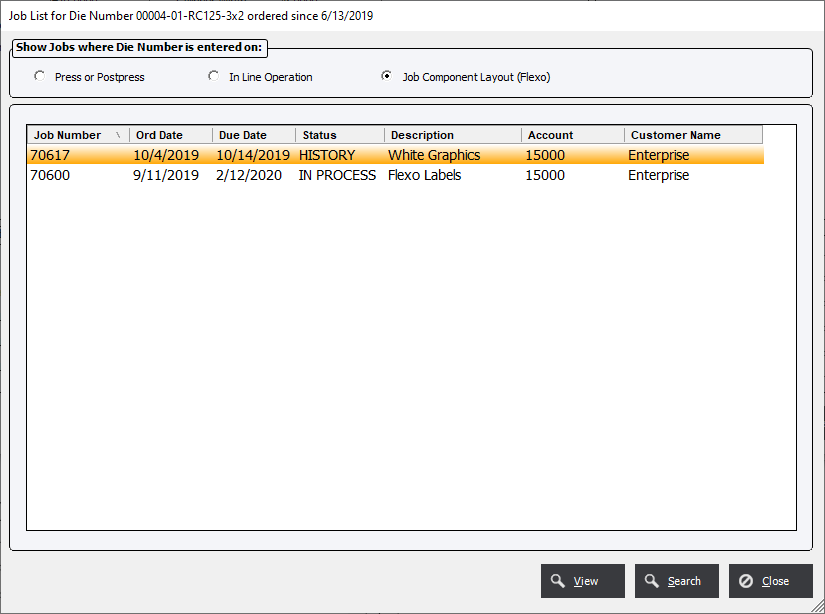

Show Jobs button : is a listing of all the jobs and their current status that have used the specific die. The feature divides the search into 3 sections; Prepress/Postpress, In-line Operations, Job Component Layout (Flexo).

The user can click the View button to jump right to the Job.