Spoilage Tables (Flexo Inks)

Updated June 14, 2022

Spoilage tables allow the user to account for running waste that will occur in a production process but because Flexo production is unique in the printing industry Eclipse allows the user to define specific spoilage tables that accommodate for a variety of color situations.

For example a certain situation might exist where if the Flexo press is running 3 colors it will need a different spoilage table than a 2 color project.

By defining different spoilage tables based on 2 dimensions (Ink colors and production quantity) the user can create a single spoilage table to automatically calculate the required spoilage.

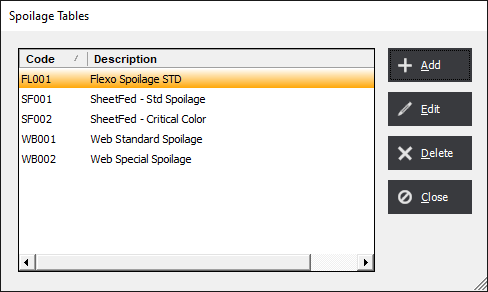

Select FileMaintenance/Tables/Spoilage Tables and the system will display the Spoilage Tables screen.

Spoilage Tables Screen

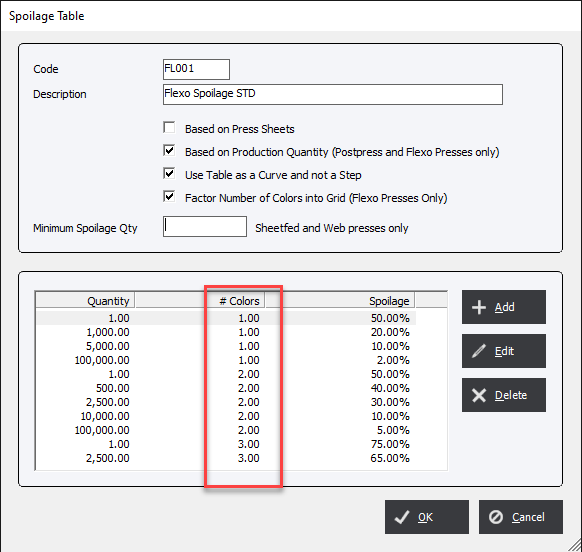

Select Add or Edit and the system will display the Spoilage Table screen.

Spoilage Table Screen

Code : 5-character, alphanumeric code that the system will use to uniquely identify the Spoilage Table.

Description : Enter a description of the purpose for the Spoilage Table.

Ensure that the following check boxes are checked:

Based on Production Quantity (Postpress and Flexo Presses only)

Factor Number of Colors into Grid (Flexo Presses Only)

Select Add or Edit and the system will display the Spoilage Table Line Item Screen.

|

Note Always start any table within Eclipse with a Quantity of 1. Tables are based on a tiered method. Any value less than the first tier will not be calculated. |

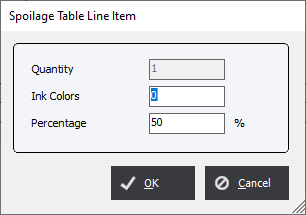

Spoilage Table Line Item Screen

Ink Colors : Enter the number of inks that will correspond to the spoilage amount.

Percentage : Enter a spoilage value that we be used to calculate the how much spoilage is required.