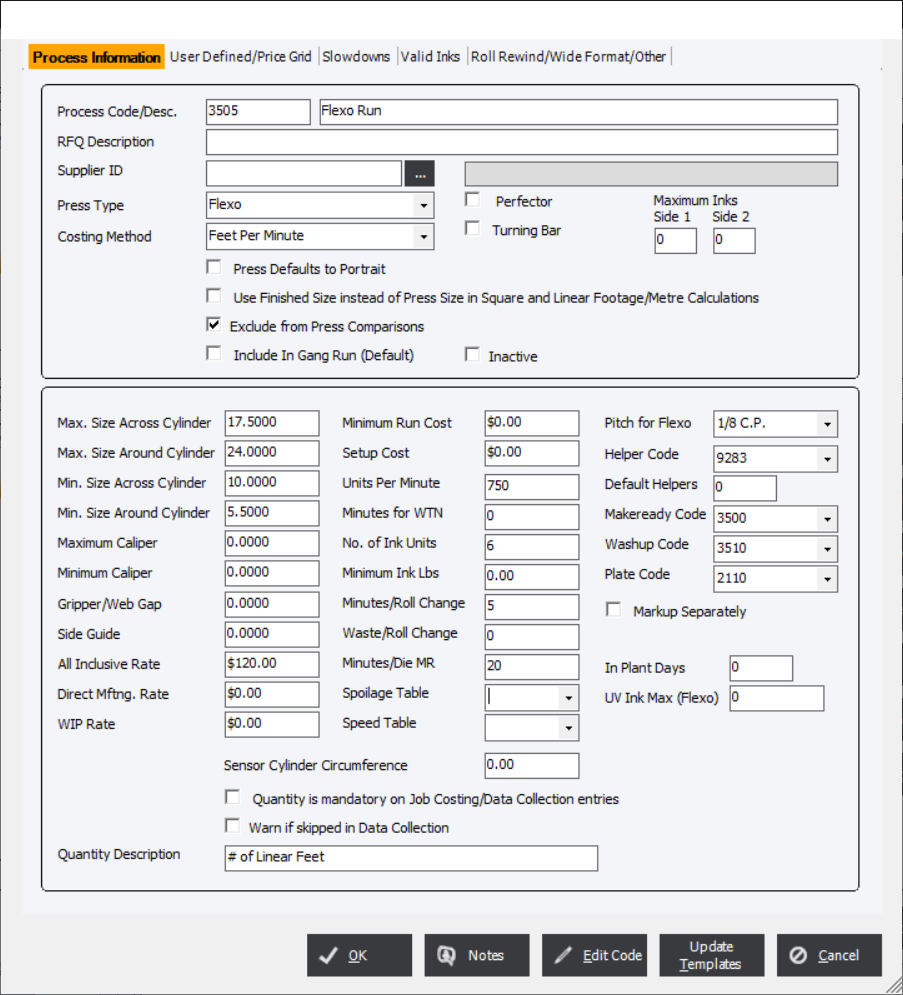

Flexo Run Process Information

Select the "Process Information" tab ("Press Process" screen) and the following screen will be displayed.

The Press Run process setup screen offers a  tab to allow the user to setup a list of Ink Material

tab to allow the user to setup a list of Ink Material

categories that are valid only for Flexo. This will limit the categories available to that press in Est/OE. If the category

list is left blank for a press it assumes that press can use all categories.

Flexo Run Process Screen

Data Fields & Options:

Maximum Inks Side One Side Two

Option: " Press Defaults to Portrait"

Double Plated Web (N/A)

Max./Min. Size Across Cylinder

Max./Min. Size Around Cylinder

Gripper/Web Gap

Side Guide

Minimum Run Cost

No. of Ink Units

Minimum Ink Lbs.

Minutes/Die MR

Option: " Quantity is mandatory on Job Costing/Data Collection entries"

Plate Code (N/A)