Speed Tables

Updated April 22, 2022

Applies to : Speed Tables for Press, HSC/Digital and Postpress Process

Speed tables allow the system to adjust the running rate for a production process. The rate is a function of the quantity of items being processed. For example, an offset press might run at an average rate of 7500 impressions/hr. for 100,000 impressions, but only 5000 impressions/hr. for 5,000 impressions.

The system allows the user to define speed tables for any production process in the following cost centers: Press, Digital/High Speed Copiers, Postpress and Bindery. Speed table factors will be percentage values based on the quantity of items being processed.

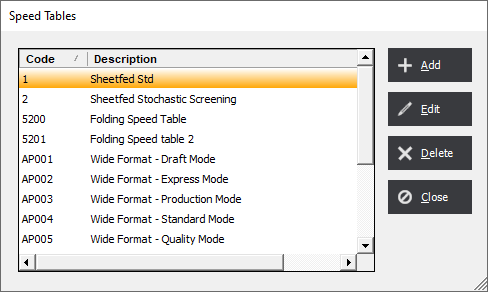

Select FileMaintenance/Tables/Speed Tables and the system will display the "Speed Tables" list screen.

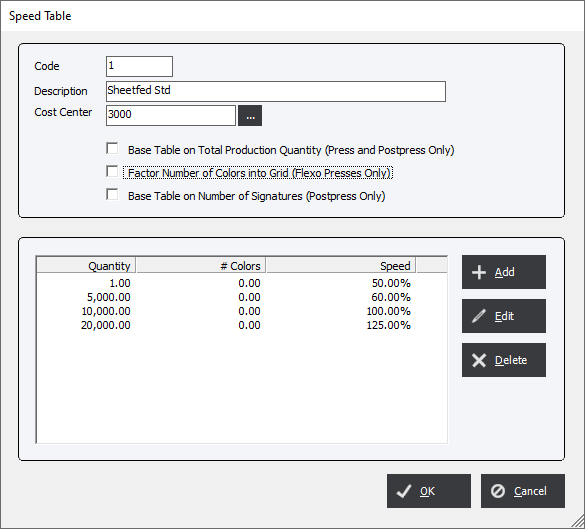

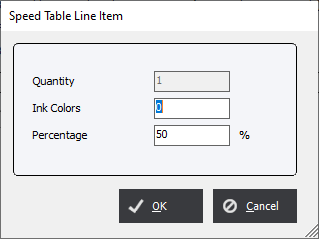

Select Add or Edit to create or modify a Speed Table for a specific purpose. Enter the steps desired and the % of the Units per Hour set in the Run Process for the Cost Center.

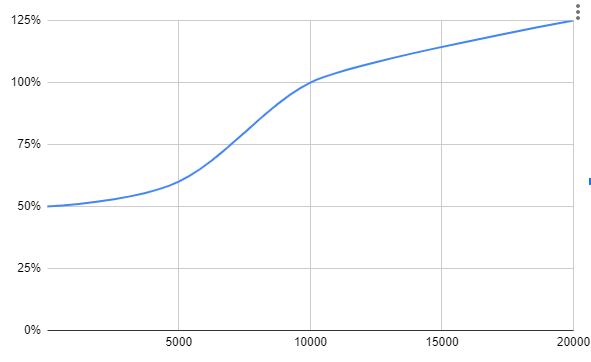

When a speed table is being used it will calculate the speed of the process based on a curve between the appropriate quantities in the table. The last quantity will always be the maximum speed of the process.

Code : 5-character, alphanumeric code that the system will use to uniquely identify the Speed Table.

Description : Enter a description of the purpose for the Speed Table.

Cost Center : Optional. If a Cost Center is chosen then it will only be available if a process from that Cost Center is added to an Estimate or Order.

If no options are checked : This option will calculate the speed based on the order quantity.

Base Table on Total Production Quantity (Press and Postpress Only) : This option will calculate the speed based on the total production quantity for the process or press.

Factor Number of Colors into Grid (Flexo Only) : For Flexo presses this option will allow the user to create multiple tables based on the number of inks used to control the speed of the press by the Total Production Quantity and the number of inks on the component.

Base Table on Number of Signatures (Postpress Only) : If chosen the other 2 options will be grayed out. This will calculate based on the number of signatures for book making, mail insert or other similar processes where the increased number of signatures/lots (ie. a Saddle Stitcher) will decrease the overall speed.

Data Grid : An unlimited number of data points can be added to the data grid. The calculations are based on a logarithmic curve between points. Grids are typically started with the value of 1 to ensure that any value is accounted for from 1 to the next data point. Any value falling above the last data point will use the last data point value to calculate the speed.

Ink colors : For Flexo presses are absolute. Speed tables will be based on the Quantity and the number of colors used to determine if the Speed adjustment is to be used.

Percentage : Enter the percentage of the base speed that the calculation will use. For example if the process has a base speed of 10,000 per hour than a 50% percentage would adjust the calculation to use 5,000 per hour as the speed of the process.