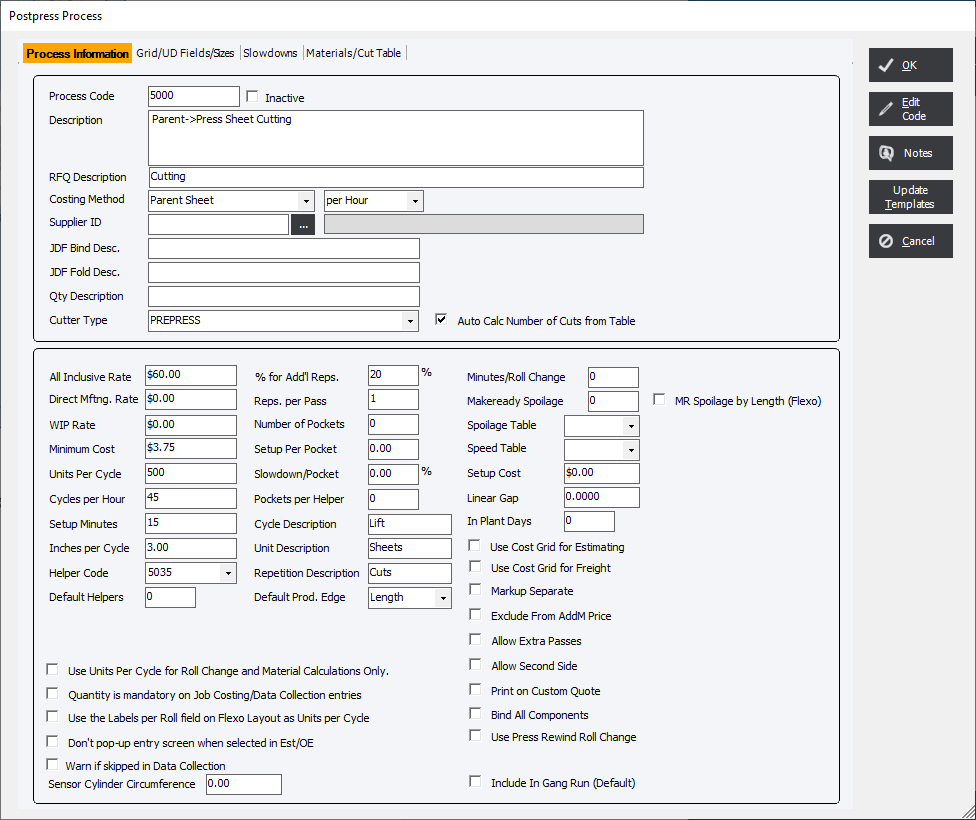

Postpress Processes

Updated November 28, 2022

Applies to : All Component Types

All Postpress processes share a common setup screen. Some options are only available with certain system settings.

Inactive : Allows the process to remain in the system but not available in new estimates or orders.

Process Code : Enter an unique integer code from 1 to 9999 (4-digits recommended) up to 9 are allowed that identifies the Process.

Description : Text that describes to the user what the process actually is for.

RFQ Description : This field applies to the Enterprise .Net online web modules.

Costing Method : Mandatory selection to determine how the process will calculate.

Supplier ID : The user may associate a Supplier with the process.

JDF Bind Desc. : Used for JDF Intergration.

JDF Fold Desc. : Used for JDF Intergration.

Quantity Description : The Quantity Description field is used as a prompt to Data Collection users to let them know what the expected quantity to input is.

Cutter Type :

Auto Calc Number of Cuts from Table : Causes the system to use the Auto Calc Cut Table to determine the No. of Repetitions for the process.

All Inclusive Rate : Sometimes referred to as Budgeted Hourly Rate this is the default method of calculating costs.

Direct Mftng. Rate : An alternative rate that can be used for calculating costs if certain options are enabled.

WIP Rate : Can be used for creating custom reports.

Minimum Cost : Makes sure calculated cost for the process will always equal or exceed this amount.

Units per Cycle : Enter the number of units for processing that will be handled in one cycle

Cycles per Hour : Enter the production running rate for the process

Setup Minutes : Enter a value to enter the time that will be required to set up the process

Inches per Cycle : If either Parent Sheets, Finish Sheets, or Press Sheets is selected as a Costing Method, and if a value is entered in the Inches Per Cycle field, then the Units Per Cycle value will be overridden by the Inches Per Cycle and the caliper of the paper stock.

Helper Code : The user may attach a helper to a process, as a default. Then, if this is done, the user may add helpers when creating an estimate in Estimating/Order Entry.

Default Helpers : This field allows the user to enter a default number of helpers.

% Add'l Reps : If the process will require more than one operation to complete a cycle (such as four cuts per lift to square cut a stock), the user will want to account for the additional time required for the additional operations (i.e. repetitions).

Reps. per Pass : This field will allow the user to define a process in which more than one operation may be performed in each production cycle.

Number of Pockets : Enter the number of pockets for the machine or process.

Setup per Pocket : Enter the set-up time, in minutes, per pocket for a collator.

Slowdown/Pocket : Enter the desired run slowdown percentage per pocket.

Pockets per Helper : Enter Pockets Per Helper and the system will calculate the number of Helpers required by dividing the total number of pockets in the Component(s) or Group by this value.

Cycle Description : Text that will replace the default text to aid the user in entering in the correct value.

Unit Description : Text that will replace the default text to aid the user in entering in the correct value.

Repetition Description : Text that will replace the default text to aid the user in entering in the correct value.

Default Prod. Edge : This will default the processes dimension when using any of the linear Costing Methods.

Minutes/Roll Change : Flexo Only(?) used for rewinding. Adds time to the Process when the material (roll) needs to be changed during the production run.

Makeready Spoilage : Entered a value that will be added to the Input Quantity of the process based on the Costing Method.

MR Spoilage by Length : Converts the value in Makeready Spoilage to absolute feet.

Spoilage Table : Accounts for running waste that will occur in a production process

Speed Table : Adjusts the running rate for a Press Run process.

Setup Cost : Value added to the calculated Press Run or Postpress process cost.

Linear Gap : Enter a value for that when using a linear calculation Costing Method requires additional space between production pieces.

In Plant Days : This option allows the user to automatically move the Job Due Date/Time from the Date/Time Ordered Date by the value in the field.

Calculation Options:

Default from Perimeter Inches (Instead of Linear) : Only appears when using Inches manual Entry Costing Method. If selected, the Inches Per Unit field in Estimating/Order Entry will be populated, as a default, with the perimeter of the Untrim/Sig Flat size (i.e. 2 x w + 2 x L). Otherwise, the default will be the L value of Untrim/ Sig Flat size. The user may override the default and enter any appropriate number.

Always Re-calculate perimeter inches based on Layout : Only appears when using Inches manual Entry Costing Method.If selected, the system will re-calculate the perimeter inches when the user edits the layout; otherwise, the system will not re-calculate and will use the previous layout value.

Use Units per Cycle for Roll Change and Material Calculations Only : Flexo - roll change only on a flexo doesn;t do division of units per cycle

Quantity is mandatory... : Select this option to ensure that when using a specific Miscellaneous process a quantity is entered into Job Costing or Data Collection.

Use Labels per Roll Field on Flexo Layout as Units per Cycle : Select this option to cause the Units per Cycle in a postpress process to match the value entered in the Labels per Roll field when entering information on the Layout/Inks tab of an Estimate/Order Entry.

Don't popup Entry screen when selected in Est/OE : This option selected will automatically add the process and the entry screen will not open.

Warn if skipped in Data Collection : This option will prompt the user if they choose a process that is out of order from the planned production.

Sensor Cylinder Circumference : Used for DMI integration.

Use Cost Grid for Estimating : Select this option and the system will determine cost based on the quantity of impressions at a Per M rate rather than a cost based on time and hourly rate.

Use Cost Grid for Freight : Calculates the freight costs based on how many Full Trucks will be require using the Max Truck Weight field in the Cost Grid for the process.

Markup Separately : Select if the process is to be marked up differently then the system default.

Exclude from AddM Price : This excludes the process from the computation (on a quotation) for Additional M's pricing.

Allow Extra Passes : This option will allow the process to be applied more than one time.

Allow Second Side : Select this option if the process may be applied to the second side of a sheet.

Print on Custom Quote : Used for the user when creating a customized quotation report.

Bind All Components : Select this option for a process and the system will use the Input Quantity from all components (within a linked group) in the computation.

Use Press Rewind Roll Change : Calculate additional setup based on the number of roll changes calculated in the Press Run process.

Use Spine Thickness : The system will use the Spine Thickness of a book (as determined in Estimating/Order Entry) and the Inches Per Cycle value to determine "books per lift".

Include In Gang Run (Default) : Allows the press to be included in any Gang Run feature.