Cost Centers Menu

Updated August 24, 2024

Cost Centers are an important aspect of the system. They are a convenience way to categorize different Processes according to their respect positions in the manufacturing process. By segregating processes this way, the system can offer different Costing Methods unique to each of their various requirements.

To accurately calculate the value of a printing estimate, many factors must be considered including labor and equipment operating cost, overhead, chargeable materials, and outside services. There may also be non-chargeable items and administrative costs that will not generally be included as direct cost but will be reflected in the equipment fully burdened overhead hourly rates.

It is important for the user to understand the difference between a Cost Center and a Process. A Cost Center is a grouping or collection of cost elements, called Processes, that will apply to production equipment or to a production work center. A Cost Center, therefore, is not a cost element and will not have an associated cost.

A Process, however, will be a cost element and will include labor and/or equipment costs, and materials in some cases, all of which may be applied to an estimate as the need arises.

The user might create Proofing as a Cost Center, and a Process within that cost center might be 12x18 Inkjet Proof.

The Process 12x18 Inkjet Proof will include the burdened labor cost to produce the proof as well as the cost of the material.

As part of system initialization, the user will define Cost Centers and Processes. Each Cost Center will be a specific Type: either Prepress, Plates, Press, Digital/High Speed Copier, Postpress or Miscellaneous Each cost center is uniquely identified by a 9 digit integer (code) from 1 to 9999. The user is advised to utilize 4-digit codes but may use up to 9. Cost Center Types are fixed within the system and may not be customized by the user.

Within each cost center, the user will also define specific Processes (cost elements) that will also be identified by a unique integer number from 1 to 9999. Again, the user is advised to use 4-digit process codes but may use up to 9.

The user should know that no two Cost Centers may have the same Cost Center Code, nor may any two Processes have the same Process Code; however, if desired, any Cost Center Code may be used as a Process Code.

EPMS recommends that Cost Centers follow a specific numbering convention in order to keep consistency throughout the system.

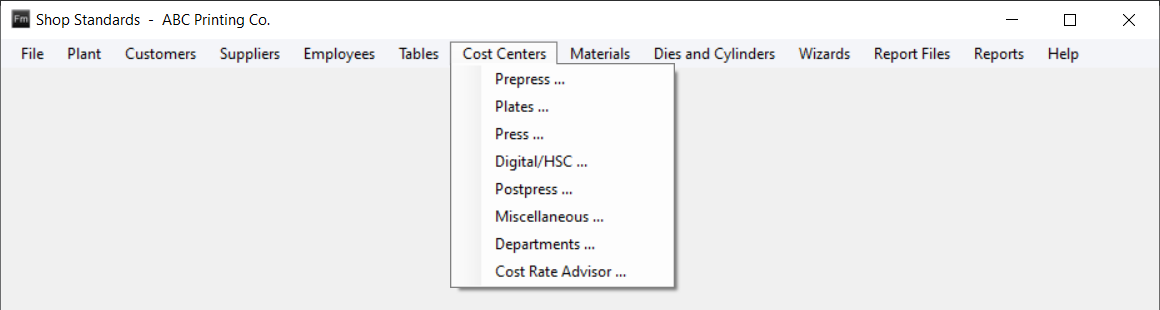

Cost Centers Menu Selection

Menu Options:

Prepress : These processes are specific to anything that happens before Press or Bindery production

Plates : This category is separated to facilitate the unique costing requirements of the platemaking process.

Press : This category is used to create processes for Litho, Web, Business Forms, Flexo, Wide Format and Apparel types of equipment.

Digital/HSC : Machines that are based on click charges are best to be set up in this category.

Postpress : These are any process that occur after printing or imaging a project. They also can contain any other type of process and have the greatest number of Costing Methods with which to calculate.

Miscellaneous : These are special types of processes that include non-chargeable items and administrative/maintenance costs that will not generally be included as direct cost.

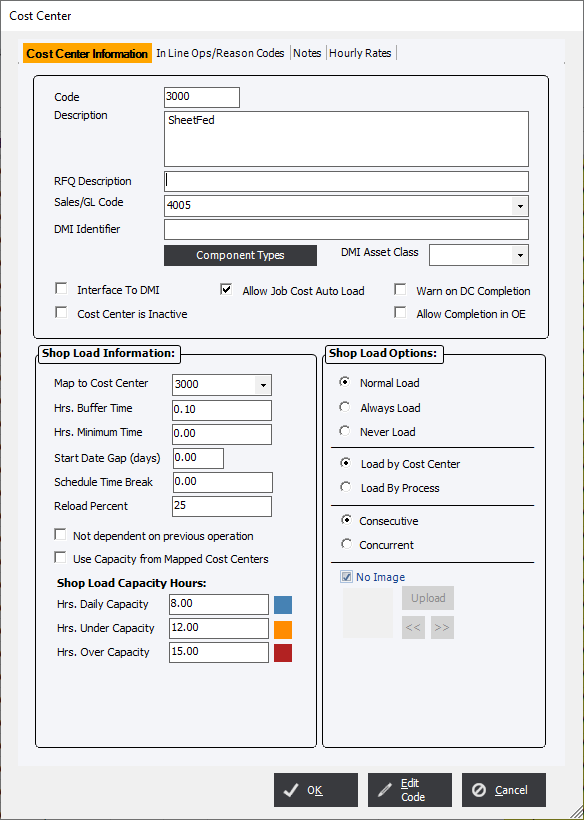

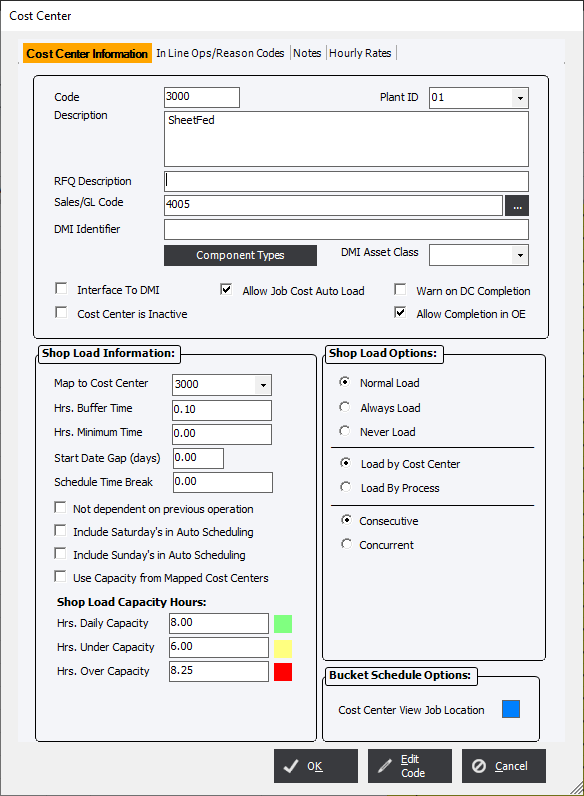

The common Cost Center Screen allows the user to enter information about each Cost Center within the Cost Cost Type and is divided into 4 tabs;

| Ghantt Scheduling Cost Center | Bucket Scheduling Cost Center |

|

|