Back Orders (Button, Shipping Screen)

Updated April 9, 2022

The Back Orders button applies only to Finished Goods shipments only.

Unless one of three options has been selected; Don’t Create Back Orders in Shipping, Always Deduct Full Shipment Qty for Finished Goods or Don't Create Back Orders for this Customer, the system will automatically create a Back Order for any Finished Goods item when a shipment is sent for less than the requested shipping count.

The system will create a Back Order after the item has been shipped, deducted from inventory, and after the job status has been changed to Complete. The user will also note that the caption on the Add button will also change to Ship BO.

Illustration:

1. Assume that there are 100 items in Finished Goods inventory.

2. Assume that an order is placed for 200 items (the system will indicate that the order exceeds the on hand quantity).

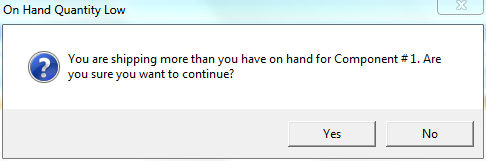

3. Create a shipment for 200 items. The system will display the following warning:

Click Yes to proceed and the system will show the shipment for 200 items. Note that a Back Order will not exist, as yet.

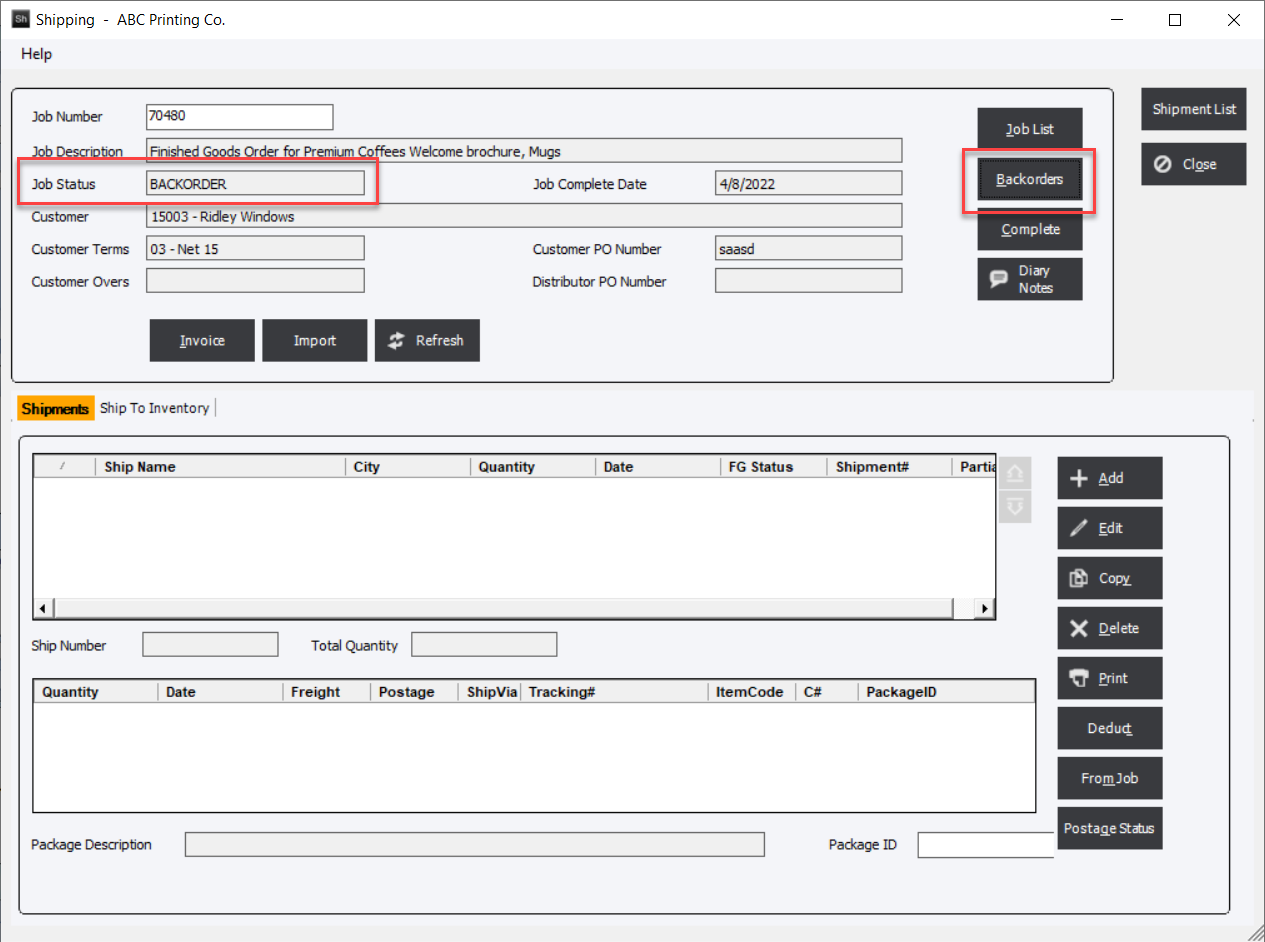

Shipping Screen

4. Select the Deduct button on the main shipment screen then click the Complete button. The system will create the Back Order. Click Back Order to display a list of back orders.

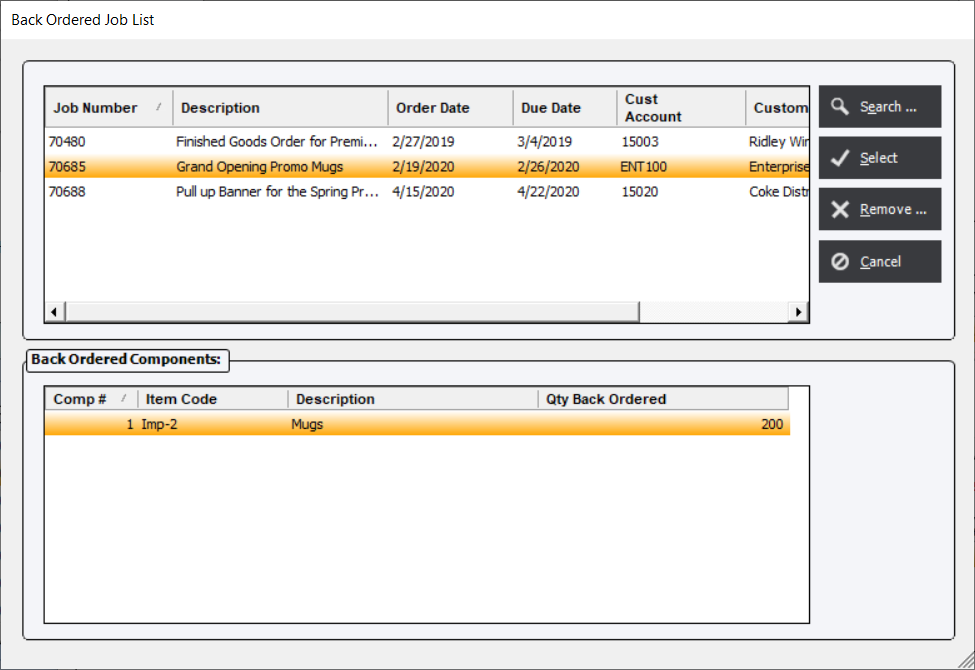

Back Ordered Job List Screen

5. When sufficient inventory has been received to fulfill the back ordered amount, access the shipment and click Ship BO. Then, Deduct the shipment.

The Back Order will be removed from the list of Back Orders. When deducting a Finished Good item the location the item was taken from can be entered. This will further enhance the effectiveness of the Finished Goods module cycle.