Sheet Material Screen

Updated November 5, 2021

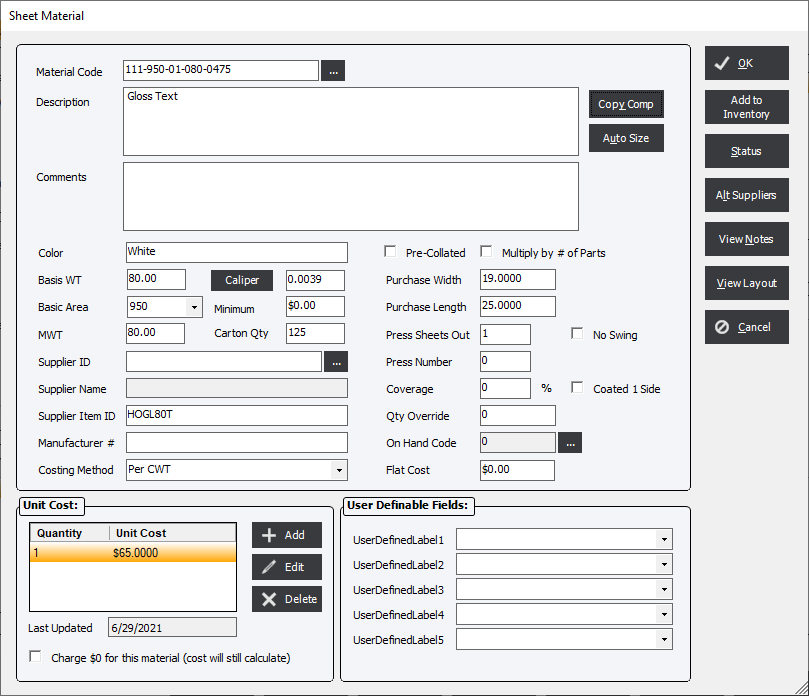

Sheetfed Material Screen

|

Changes made to any material brought in from Inventory or the Material Section of File Maintenance will not change the information stored in those sections. It will only pertain and be saved with the estimate or order. |

Data Fields (click following to view):

Material Code : Select the  button to navigate and select an item that has been defined in the Paper Material Section of File Maintenance

button to navigate and select an item that has been defined in the Paper Material Section of File Maintenance

Description : Description of material.

Comments : Enter comments here that will be added to the Job Ticket for any special material handling.

Copy Comp Button : This button will copy the contents of the Detailed Description IF the Description on the Sheet Material is blank.

Auto Size Button : If the same stock is in the system with different parent sizes the system will choose the one that has the least amount of waste.

Color : Color of the material.

Basis WT : Basis Weight (BWT) is the weight of 500 sheets (one ream) of Basis Size paper. Therefore, 500 sheets of 25x38-60 BWT offset paper would weigh 60 lbs.

Caliper Button : This will initiate this formula as long as the Material Category of the item has a Caliper Factor that it belongs to and a BWT > 0.

Caliper Field : Caliper thickness of the stock is either entered in manually in an order or retrieved from stock that has been added to an item of material in File Maintenance or Inventory.

Basic Area : Select the Basic Area of the Basis Size of the type of paper.

Minimum : Enter an amount that will act as a minimum cost if the calculate cost of the item does not reach this level

MWT : This field allows the user to bypass the Basis Wt. and Basic Area for weight calculation

Supplier ID : (Optional) Choose from the supplier list.

Supplier Item ID : (Optional) Enter a Item ID from the vendor if one is available.

Manufacturer # : (Optional) Enter a manufacturer # if one is available.

Costing Method : Choose the costing method.

Precollated : Controls how stock requirements are calculated when the Parts to Print field in the Layout tab is greater than 1.

Multiply by # of Parts : Typically this option is used as one of the methods of printing pads or carbonless sets where the same image is repeated and all parts.

Purchase Width : Enter the width of paper purchased from the vendor. This will translate into the Parent Width.

Purchase Length : Enter the length of paper purchased from the vendor. This will translate into the Parent Length.

Press Sheet Out : Calculated based number of out from Parent Sheet.

No Swing : Forces the number out from Parent to Press Sheets to not include swing cut.

Press Number : This allows the paper, presses and inks to be defined to specific press numbers.

Coverage % : This field is applicable when only a portion of the sheet will be involved, such as for a laminating process. The material costing method should be MSI or equivalent. Enter a percentage and the system will reduce the quantity accordingly – e.g. 10% would indicate 10% coverage. If 0% is entered (default), the system will assume 100% coverage of the sheet.

Coated 1 Side : If the paper is Coated 1 Side. This will restrict the Imposition style to SHEETWISE or WORK AND SWIRL.

Qty Override : The system will allow the user to enter an exact amount of stock to be used for a press run. For example, the user might want to enter makeready sheets (using a less expensive stock) that would be independent of the press run. To do this, enter a quantity in the "Qty Override" field. This feature only applies to Sheetfed and Digital/HSC jobs.

On Hand Code : On Components; Sheetfed, Digital/HSC and Business Forms when selecting a stock the On Hand Code button allows the user to define from which default location to take use from Data Collection.

Unit Cost

Flat Cost : The Material Flat Costs are costs that will be added on top of the calculated cost based on the cost method.

Unit Cost : Use this field to define a cost grid that will be used for a specific material. It is recommended that the user start the grid with quantity = 1.

Charge $0 for this material (Cost will still calculate) : This option and the system will calculate the cost of the material but will not include that cost into the overall price of the job.

Buttons

Add to Inventory : The user may enter a sheet stock for an estimate that is not maintained in inventory. Additionally, the paper may be added to the inventory “on the fly” by clicking the Add to Inventory Paper button.

Status : Click the Status button and the system will display the current status of an inventory item.

Alt Suppliers : The user may want to choose to buy a specific material from an alternate suppliers

View Notes : Any notes written in the Notes Section of the specific Material Items.

View Layout : This button will allow the user to print a layout diagram for each stock when several stocks are added for a Sheetfed or a Digital component.

Users Defined Fields : There are 5 User Defined Fields for the user to use.