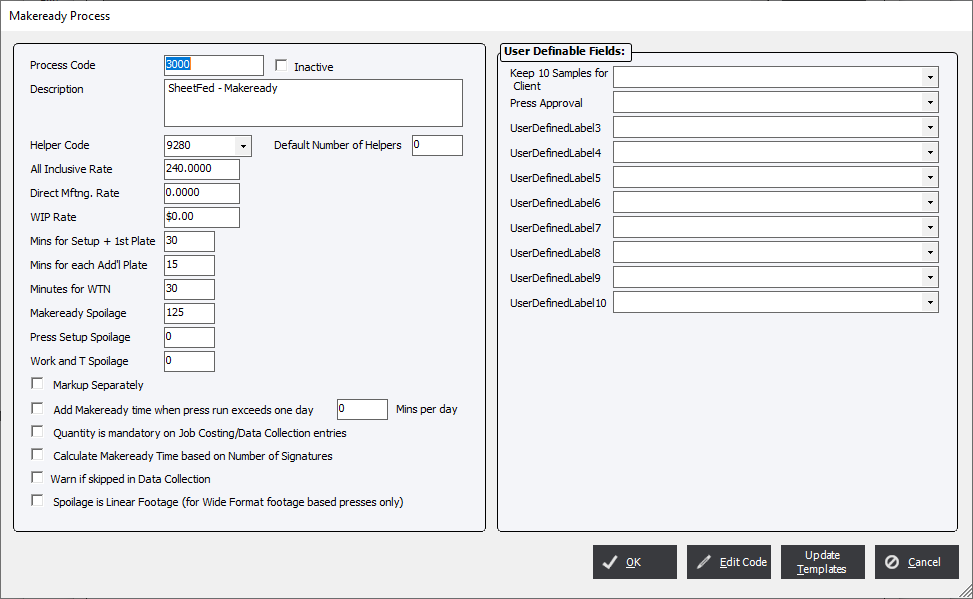

Press Makeready Process

Updated August 18, 2022

Applies to : All Press Processes

The Makeready process allows the user to define how much in time is required to set up the press before the "on count" running starts.

Inactive : Allows the process to remain in the system but not available in new estimates or orders.

Process Code : Enter an unique integer code from 1 to 9999 (4-digits recommended) up to 9 are allowed that identifies the Process.

Description : Text that describes to the user what the process actually is for.

Helper Code : The user may attach a helper to a process, as a default. Then, if this is done, the user may add helpers when creating an estimate in Estimating/Order Entry.

All Inclusive Rate : Sometimes referred to as Budgeted Hourly Rate this is the default method of calculating costs.

Direct Mftng. Rate : An alternative rate that can be used for calculating costs if certain options are enabled.

WIP Rate : Can be used for creating custom reports.

Mins for Setup + 1st Plate : Enter the time required to makeready the press, including the first press plate.

Mins for each Add'l Plate : Enter the time required to makeready additional press plates (after the first plate).

Minutes for WTN : Allows the user to set additional Makeready time for jobs the have the imposition set as Work and Turn or Work and Tumble in the Layout tab.

Makeready Spoilage : Enter the setup sheets/cutoffs in this field which will be independent from the run spoilage.

Press Setup Spoilage : Allows the user to default an exact amount of material spoilage independent of Makeready Spoilage.

Work and T Spoilage : Enter a value in this field so that when an Estimate or Order has an Imposition set to Work and Turn or Work and Tumble.

Markup Separately : Select if the process is to be marked up differently then the system default.

Add Makeready time when the press run exceeds one day : Enter additional makeready and/or wash time can be added when the press run of an Estimate or Order exceeds the capacity for the Cost Center.

Quantity is mandatory... : Select this option to ensure that when using a specific Miscellaneous process a quantity is entered into Job Costing or Data Collection.

Calculate Makeready Time based on Number of Signatures : Will calculate Makeready time based on the total for the number of Sigs/Lots using the number of Plates/Inks etc in the layout screen information.

Warn if skipped in Data Collection : This option will prompt the user if they choose a process that is out of order from the planned production.

Spoilage is Linear Footage (for Wide Format footage based presses only) : This option changes the Makeready Spoilage from being based on the Parent Size to strictly based on Linear Footage.

User Definable Fields : The User Defined Fields or UDF's menu selection will allow the user to define custom fields.

Edit Code : The Edit Code button allows the user to change the Process Code to a new value.

Update Templates : The Update Templates button may be used to decide whether or not to update associated templates when a change is made to a processes.