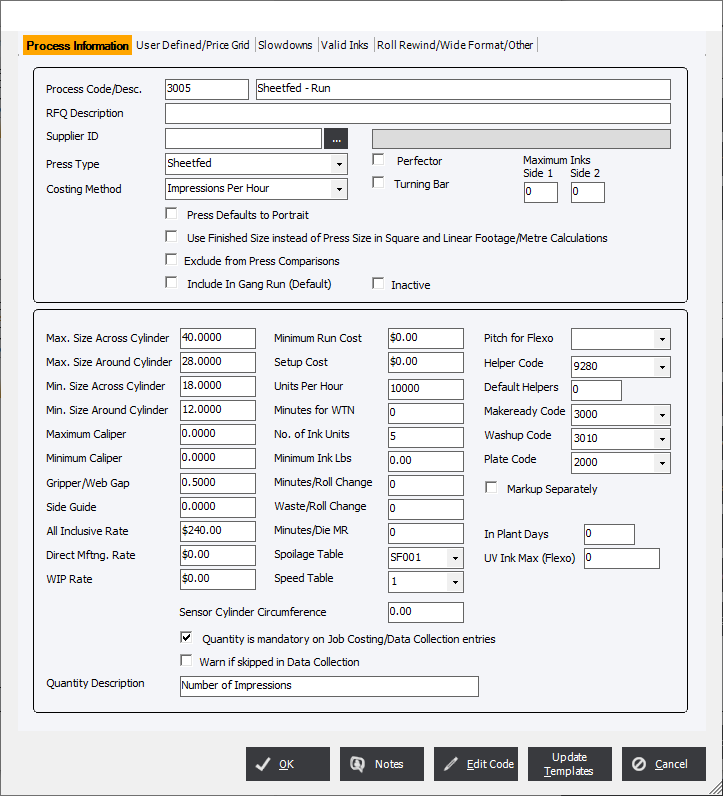

Press Run Processes

Updated October 19, 2022

Applies to : All Presses

All Presses processes share a common setup screen. Some options are only available when certain Press Types are chosen.

Inactive : Allows the process to remain in the system but not available in new estimates or orders.

Process Code : Enter an unique integer code from 1 to 9999 (4-digits recommended) up to 9 are allowed that identifies the Process.

Description : Text that describes to the user what the process actually is for.

RFQ Description : This field applies to the Enterprise .Net online web modules.

Supplier ID : The user may associate a Supplier with the process.

Press Type : Select one of the following Press Types - Sheetfed, Web, Business Forms, Flexo, Digital or Embroidery. Selecting a specific Press Type will change the screen to offer different options.

Costing Method : Will change to reflect the specific Press Type chosen.

Perfector : A Perfector press allows the press to run both sides of the sheet with one pass.

Turning Bar : Used for a web perfecting press that will use a turn bar to turn the sheet for printing on the reverse side.

Double Plated Web : Refers to a type of press that will likely be used for high quantity press runs where a minimal amount of added Makeready time and spoilage balanced against shorter run time is worthwhile.

Press Defaults to Portrait : In the case where a press cylinder is longer than it is wide it can be defined as defaulting to printing portrait.

Use Finished Size instead of Press Size in Square and Linear/Metre Calculations : Causes the system to calculate square or linear foot cost using the component Untrim/Sig Flat (Sheetfed component) or Untrim Size (Wide Format component) rather the Press Sheet size.

Exclude from Press Comparisons : During an Estimate or Order the user has the option to compare the production specs against multiple presses. This option will exclude the press from the list of presses that can be compared.

Include In Gang Run (Default) : Allows the press to be included in any Gang Run feature.

Max. Size Across Cylinder : Refers to maximum Press Sheet Width rather than image sizes.

Max. Size Around Cylinder : Refers to maximum Press Sheet Length rather than image sizes.

Min. Size Across Cylinder : Refers to minimum Press Sheet Width rather than image sizes.

Min. Size Around Cylinder : Refers to minimum Press Sheet Length rather than image sizes.

Maximum Caliper : Sets the Maximum Caliper thickness of material that can be used on the Press Type.

Minimum Caliper : Sets the Minimum Caliper thickness of material that can be used on the Press Type.

Gripper/Web Gap : Subtracts from the Width of the Press Sheet reducing the area to calculate the number of Outs.

Side Guide : Subtracts from the Length of the Press Sheet reducing the area to calculate the number of Outs.

All Inclusive Rate : Sometimes referred to as Budgeted Hourly Rate this is the default method of calculating costs.

Direct Mftng. Rate : An alternative rate that can be used for calculating costs if certain options are enabled.

WIP Rate : Can be used for creating custom reports.

Minimum Run Cost : Makes sure calculated cost for the process will always equal or exceed this amount.

Setup Cost : Value added to the calculated Press Run or Postpress process cost.

Units Per Hour : Enter the speed per hour of the press which is based on the Costing Method.

Minutes for Work & Turn : Allows the user to set additional Makeready time for jobs the have the imposition set as Work and Turn or Work and Tumble in the Layout tab.

No. of Ink Units : The field indicates how many ink units there are on the press.

Minimum Ink Lbs : The system will use the Minimum Ink Lbs if the ink material required in an Estimate or Order is less then this value.

Minutes/Roll Change : Adds time to the Press Run Process when the material (roll) needs to be changed during the production run.

Waste/Roll Change : The Waste/Roll Change calculates the additional material required to perform the roll change.

Minutes/Die MR : Defines additional makeready time when a die is added via an In-Line Operation to a press process in an Estimate or Order.

Spoilage Table : Accounts for running waste that will occur in a production process

Speed Table : Adjusts the running rate for a Press Run process.

Pitch for Flexo : Allows the system to use either the 1/8 C.P. or 32 D.P. methods to calculate number of teeth required for the the user to choose the correct plate cylinder accurately.

Helper Code : The user may attach a helper to a process, as a default. Then, if this is done, the user may add helpers when creating an estimate in Estimating/Order Entry.

Default Helpers : This field allows the user to enter a default number of helpers.

Makeready Code : Defines how much time is required to set up the press before the "on count" running starts.

Washup Code : Can be added as a default that will be used with Inks that require a Washup.

Plate Code : Defaults a specific type of plate to the press.

Markup Separately : Select if the process is to be marked up differently then the system default.

In Plant Days : This option allows the user to automatically move the Job Due Date/Time from the Date/Time Ordered Date by the value in the field.

UV Ink Max (Flexo) : Sets the maximum number of ink units on a Flexo press are able to print with UV Inks.

Sensor Cylinder Circumference : Used for DMI intergration.

Quantity is mandatory... : Select this option to ensure that when using a specific Miscellaneous process a quantity is entered into Job Costing or Data Collection.

Warn if skipped in Data Collection : This option will prompt the user if they choose a process that is out of order from the planned production.

Quantity Description : The Quantity Description field is used as a prompt to Data Collection users to let them know what the expected quantity to input is.